Can You Have Too Many Nails In 2x4 Wall

Wood Framing Toe-Nailing Connections

Wood Framing Toe-Nailing Connections

Guide to using slant-driven nails for wood framed joists, studs, sill plates, top plates, & beams

- POST a QUESTION or Annotate about toe nailing in woods frame structure

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Woods frame toe nailing: how to toe-nail joists, studs, & beams in wood framed structures.

This article describes the proper method for strong "double-shear" angled or toe nailing of joists or studs that butt into beams or summit or shoe plates in wood framed buildings.

Properly washed, toe-nailing makes very potent wood framing connections. Merely mistakes similar choosing the wrong nail size, wrong nail placement, or wrong number of nails tin can mean weak joints and a weak construction.

Wood framing connections & connectors: this article series explains the proper selection and installation of structural connectors, brackets & tie plates used to connect deck or porch framing and support members.

We also provide an ARTICLE Index for this topic, or yous tin try the page top or bottom SEARCH BOX as a quick fashion to find information you lot need.

Guide for Toe Nailing Wood Framing Connections

Definition of toe-nailing: framing nails driven on an angle from opposing sides and through the nailed-through wood framing member into the nailed-to framing member so that the "crossed" opposed toe-nails class both a shear-resistant and a withdrawal-resistant connection betwixt the framing members.

Definition of toe-nailing: framing nails driven on an angle from opposing sides and through the nailed-through wood framing member into the nailed-to framing member so that the "crossed" opposed toe-nails class both a shear-resistant and a withdrawal-resistant connection betwixt the framing members.

[Click to overstate any image]

Toe-nailing or slant-driven nails are commonly used where it is non possible to drive through the side plate or top plate into the framing member, and has been historically widely used for connecting studs to the meridian or bottom plate, beam to plate, and rafter to plate or ridge lath connections.

We will illustrate several of these toenail or camber-nail connections in this article.

Toe-nailing is used both stand-alone, without steel framing connectors and also toe-nailing is specified for the installation of some (not all) framing connectors.

In carpentry schoolhouse nosotros were taught that provided yous use the right type and size fastener (mutual nails, construction screws) and the right number of them (at that place are tables and standards) toe-nailed from both sides of the abutment of a stringer face to the floor joist (or rafter to ridge and rafter to top plate, or stud to top and bottom plate) the connection is completely adequate, and is as strong every bit that made using proper joist hanger nails and joist hangers.

You will come across that in that location are many opportunities to make a bad connection using either approach, in particular, using improperly-sized, placed, or number of fasteners. There is no evidence in my experience that people make fewer mistakes using a joist hanger than using straight nailing. They just brand dissimilar mistakes.

Definition of shear loading & lateral loading of forest framing connections:

Shear loads or lateral load are beyond the framing nails while withdrawal loads are those that tend to pull the framing nails out of the nailed-to fellow member.

Toe-Nails Instead of Joist Hangers are OK for Framing Lumber Butt-Joint Connections, simply Don't Over-Nail and Don't Under-Nail

Information technology is non necessary to use steel joist hangers if the joist is properly toe-nailed from either side into the ledger board, provided that the proper size and number of nails are used.

See FRAMING CONNECTORS & JOIST HANGERS for details most those connectors.

Our illustration (to a higher place left, adjusted from a Double-Shear stamping on a steel joist hanger) explains why toe-nailed lumber connections can be very stiff.

We drew in spray-chocolate-brown color, a representation of wood framing members showing the abutting of 2x lumber (vertical in the illustration) with a header or beam (horizontal in the illustration).

The crossed nails, when practical close together (as guided by the framing connector or by the hand of a competent framing carpenter), form a very strong woods-to-wood connection.

The crossed nails, when practical close together (as guided by the framing connector or by the hand of a competent framing carpenter), form a very strong woods-to-wood connection.

Employ of toe-nailing, or angled opposed framing nails (Double-Shear in Simpson Strong-Necktie's patented[ten] joist hanger such as the detail adjusted above), tin can permit the use of fewer total nails in a woods frame structure.

Our photo at left shows an unsuccessful use of toenailing in a failed endeavour to connect intersecting glulam beams. The nails (those brown spots) pulled, broke, aptitude, and allowed the connexion to neglect.

The steel Lally columns are besides not properly located an installed.

These beams are non properly connected and their structure is in danger of plummet. That some movement has already occurred is evident in the gap to a higher place my tape measure.

The strength of a toe-nailed wood framing connection will be affected by:

- How shut to opposite one another the two nails are placed

- Using nails of sufficient length to adequately penetrate both forest members

- Nailing the toe-nails at the proper angle (45 degrees).

- Placing nails loftier enough from the edges of the abutting member (vertical in our sketch) equally to have adequate buy and to avoid only splitting out a petty flake of the edge of the 2x.

- Placing nails depression plenty in that same member to be certain that the length of the boom penetrates both the abutting member and the nailed-to facing member.

- Using the correct number of nails specified for the lumber sizes involved.

- The species and form of the lumber being used and of class the condition of the lumber

- The blazon of loading: shear loading or lateral loading versus withdrawal loading that will be applied to the connection

How Many Nails to Utilize When Toe-Nailing

Because the "toe-nails" cross one some other in the header or ledger lath when used to secure a deck joist, this connection can actually be stronger than straight-in or end-nailing the deck joists from the other side of the ledger or girder.

But using too many nails (below left) or also few nails (below right) is a mistake that results in a weak connection and potentially an unsafe structure.

Using Too Many Nails when Nailing Wood Framing

Using too many nails in a framing lumber connection when toe-nailing or in any position for that matter will also cause a weak framing connection that can atomic number 82 to structural plummet.

That's because an excessive number of nails actually fractures the lumber. If you click-on and overstate our photo at to a higher place left y'all'll meet that the contractor fractured the vertical stud near its summit. Our photo (left) shows about xxx nails shot by the builder during framing of this dwelling house.

The framer was trying to bulldoze a recalcitrant stud into position. Clamps might take worked better.

This stud was so split as to lose its structural integrity, and replacement of this wall stud was needed.

As we prove beneath, adding more nails, even with a pneumatic nail gun, does not exercise a keen job of pulling together framing members that are separated.

As well few nails when toenailing framing

Using too few toe-nails in a framing lumber connectedness is going to brand a weak construction that could plummet.

For code compliant nailing run across the nail schedules in the applicable building lawmaking for your area. For example see the UBC Tabular array 25-Q Nailing Schedule. A few examples are cited beneath.

- Studs: 2x4: iv nails - In the bottom of a 2x4 stud we utilise two nails per side, opposite ane another, crossing in the nailed-to member.

- Studs, 2x6: 6 nails - In the bottom of a 2x6 stud nosotros'd use 3 (and in some cases 4) nails per side.

- Joist to ledger board: varies by joist depth.

In a 2x6 joist I'd utilize 8 nails, four per side.

- Rafter toenail connections:

At the birds' mouth cut of a rafter connecting to the acme plate we employ three nails per side, two downwards through the top of the birds' oral fissure into the top plate and one (on either side) of the rafter's vertical portion of the bird's rima oris cut into the face of the peak plate.

Really? Well yeah, in traditional wood framing nosotros toe-nail the rafter to the top plate at the birds oral cavity cutout. Still depending on the location of the structure and framing practices, the builder may use a framing ballast specifically designed for joining a rafter to the top plate of the wall.

Our photograph above shows a bird's mouth notch in a porch rafter sitting atop the outer girder - equivalent in location and rafter measurements to setting a rafter atop the wall height plate of a edifice wall.

In a properly-cutting bird'due south mouth, the length of the horizontal or level line (below my ii red arrows in the photo in a higher place) should be nearly equal in length to the width of the top plate.

The actual design of the bird'due south mouth cut volition vary in both length and depth according to the width of the top plate, the angle of the roof, the pattern of the roof overhang and also the use of framing connectors.

Some framing anchors eliminate the birds mouth notch; a framing anchor provides a steel nailing plate connector that provides a stronger connection with better hurricane or storm wind resistance. Similar special connectors are provided for connection of the rafter to the ridge.

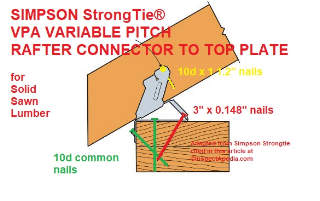

Above: a Simpson Strongtie® VPA variable pitch rafter-to-wall connector designed for solid sawn lumber. Discover that using the VPA rafter connector the bird'south mouth cutting or notch is eliminated. [Click to overstate whatsoever image]

Below: a Simpson Strongtie® H1.81Z Hurricane Tie designed for LVL roof rafters to give a stronger connection to the meridian plate

At the ridge the rafter is toe-nailed to the ridge board OR a steel framing connector can exist used. Below my photo shows separation between the rafter confront and the ridge board.

Below: questionable rafter-to-wall connections

Above: 2 visible, possibly four maximum, toe-nails through rafter ends along with some other rather odd wood framing in a U.S. home inspected by the author.

In my OPINION (not an engineering opinion) and from what we tin can see, these rafters are non adequately connected to the residuum of the structure.

- Girder or beam to post, plate or other connections: must be specified by the design

Examples of Nailing Schedule for Toe-Nailed or Slant-Nailed Wood Framing Connections | |

| Forest Frame Connection Type | Number of Nails Required |

| Blocking or Bridging, between joists / rafters | iii-8d into top plate 2-8d into joists at each end of the block or bridging |

| Ceiling joist to top plate of wall | three-8d toenails - 12d |

| Cross bridging between joists | two-8d nails |

| Header to studs | 4-8d - 12d toenails 2 on opposing sides |

| Rafter to surface of top plate | 3-8d - 10d - 12d toe-nails (run into notes in text in a higher place), besides 10d box nails may be used in some jurisdictions. |

| Floor joists or ceiling joist to elevation surface of sill plate or girder top | 3-8d mutual toenails, or 10d, or 12d |

| Floor joists or deck joists to ledger board face | 4-6 8d or 10d toenails per side, 2x6 joist; number per side increases for deeper joists; |

| Joist & rafter blocking | 3-8d, face nail from ii nails from 1 side |

| Rim joist to surface of top plate or sill plate | 8d, six" o.c. |

| Wall stud (2x4) to top plate | 2 - 16d end-nails (through the plate from below, into the stud terminate) |

| Wall stud (2x4) to sole plate or "shoe" | 4 - eight-d toe-nails or ii - 16d end-nails (through the plate from beneath, into the stud finish) |

Notes to & Complete Nailing Schedule Sources for table higher up

- Nail FASTENING SCHEDULE - 2016 CALIFORNIA BUILDING Lawmaking Table 2304.10.1 [PDF] Edifice & Safety Partitioning, Plans & Permits Div., City of Fremont California, 39550 Freedom St., Fremont CA 94538, Website: www.fremont.gov, original source: https://www.fremont.gov/DocumentCenter/View/7140/FASTENING-SCHEDULE?bidId=

- NAILING SCHEDULE - 1994 Uniform Building Lawmaking Tabular array 23-I-Q [PDF] - this PDF provides the unabridged wood framing nailing table that serves every bit a general guideline on number of toe-nails used and nail size used for diverse residential forest framing connections.

- RESIDENTIAL NAILING SCHEDULE Table R602.3(ane) FASTENER SCHEDULE for STRUCTURAL MEMBERS [PDF] Dublin CA Building & Condom Partitioning, 100 Borough middle Plaza, DublinCA 95468 USA, Tel: 925-833-6620 website: dublin.ca.gov

- IRC Code: IRC–12/thirteen Tabular array R602.three(1) Fastening Schedule for Structural Members

Other code & data source citations for nailing schedules are given below

Watch out: It is essential that nails be driven from both sides of the member for a proper toe-nailed connection.

How to keep the framing member in position when toe-nailing

Framing tip : if you've marked the stud, rafter, or joist location on the nailed-to plate or ridge board you lot may find that as you toe-nail the first nail into the side the nailed-through member begins to slide past the placement line.

If the movement of the nailed-through member off of the layout line is one/8" or less, go ahead and cease the first nail, but so starting time the second smash on the reverse side of the nailed-through member. Every bit you stop that boom you will drive the nailed-through member back to its exact position on the layout line.

If the move off of the layout line is more than 1/8", stop nailing the start toe-nail and outset the second contrary-side toenail to move the member back into position.

Rather than tippy-tap back and along on the ii sides, you should be able to fully drive the 2d nail fifty-fifty if it moves the fellow member back over the layout line upwardly to ane/eight" in the opposite direction. When you stop nailing the first toenail yous'll drive the member dorsum into perfect position.

Then finish the remaining toenails, taking turns to boom from opposing sides.

Where to Place the Nails When Toe-Nailing

at left is an example of angle or camber nailing that is non "toe nailing" because the nails for each connection are existence driven into only one side of the mated wood members. That'southward ok for this application.

at left is an example of angle or camber nailing that is non "toe nailing" because the nails for each connection are existence driven into only one side of the mated wood members. That'southward ok for this application.

Incidentally, y'all may notice that the joist bridging shown at left was nailed at its upper terminate before the subfloor was set in place. But no one remembered to stop the job. The nails in the bridging ends show proper placement and bending for nailing into the joist bottom edges.

Offset let'south sympathize the objective: nosotros want the toe-nailed nails to reach the following:

- Avoid splitting the nailed-through member: this means don't starting time the toenail to close to the very stop of the nailed-through fellow member. Usually 3/4" to one 1/4" before the end of the nailed through fellow member will work.

- Obtain sufficient depth or bite into the nailed-to framing member. This means we desire 3/4" or more of nail fully into the trunk of the nailed-to member. Cull a nail of the right size (meet below) and right location to attain this.

If y'all're non sure most the bending (about 50° to threescore° up from horizontal) or starting location of your blast from the end of the fellow member, hold your toenail across an example of the to-be-connected lumber where the end of the nailed-to fellow member is visible. You'll be able to see the depth to which it's going to penetrate.

Toenail or Slant-nailing Spacing Specifications | |

| Location | Minimum Clearance Distance |

| Minimum cease-altitude to starting time the toenail: | vii/viii" |

| Minimum edge distance to start the toenail | seven/8" |

| Minimum center-to-center distance for spacing toenails | 1 3/4" |

Notes to the table above

Some model edifice codes such as the UBC specify the spacing for camber nailed or toenailed connections, with differing requirements depending on whether the objective is to reduce shear loading or lateral loading versus withdrawal loading.

Building code specifications for nailing schedules as well include assumptions about the wood species and grade, typically Douglas-fir/larch or Southern Pine lumber.

What size nails should be used for toe-nailing

Our photo (left) shows a built-upwardly girder sitting atop a wood post with no visible connection.

Our photo (left) shows a built-upwardly girder sitting atop a wood post with no visible connection.

But in my Stance the typical "toenailing" of this girder to the mail service acme that some builders may apply would even so be an inadequate connexion.

This connexion, discussed in detail at FRAMING CONNECTORS & JOIST HANGERS, is an dangerous structure that risks collapse.

Reader question: (July 22, 2012) Ron said: 3" or three i/4" for toe nailing 2x lumber?

Answer: Ron,

In the article in a higher place yous can meet an illustration of toe-nailing showing nails crossing into the nailed-to member for strength.

- The required nail size for toenailing or slant-nailing depends on the application, location, type of connectedness, and size of lumber involved.

- The boom size too affects the number of nails required.

- For example in connecting a wall stud to the sole plate we use 2 end-driven 16d nails OR iv 8d toenails.

- As another example, where making structural connections of larger lumber sizes using 16d (iii one/ii") common nails, the Uniform Building Code (UBC) requires 1 iii/four" of penetration into the nailed-to member.

- For nailing typical 2x studs to a bottom plate or top plate the UBC requires 4 8d common nails, two per side of the stud.

- A 3-inch nail or 10d nail would exist large plenty for most common framing situations. In fact some framing texts (Wagner, Willis H, "Modern Carpentry" (1976)) describe using four 8d toenails, nearly likely again out of a business organisation to avert splitting problems.

Driven a properly-sized nail on a proper angle through the 1 1/2" of thickness of 2x lumber yous've got one- three/4" bite into the lumber below;

Toe nailing tin be quite strong if properly installed - with nails in pairs assault opposing sides and at opposing angles so that they "cross" within the nailed-to wood. Just if "toe nailing" is done just from one side the framing connection is not stiff and in my opinion non proper.

It'south also important to locate the toenail correctly - if information technology's too shut to the lesser of the vertical stud or cease of the horizontal framing joist it will split up the wood and won't have enough bite in the nailed-through fellow member.

If on the other hand the toenail is as well high in the nailed-through member information technology won't have enough bite in the nailed-to member. I toenail about an inch from the end of the nailed-through member and on an angle that I can visualize as sending a skillful portion of the blast into the torso of the nailed-into member.

How to avoid splitting when toenailing or slant-nailing woods framing

Start past keeping the toenails a sufficient altitude from the cease of the nailed-through member simply not so high that you won't have adequate penetration into the nailed-to member.

Start past keeping the toenails a sufficient altitude from the cease of the nailed-through member simply not so high that you won't have adequate penetration into the nailed-to member.

In our photograph at left I point out the location of two of the four required toenails for nailing the rafter to the superlative plate at the birds' oral cavity cutting.

I don't run into whatsoever splitting but I'grand worried that the nails may be a bit loftier. Depending on the size of nail used in that location may not be adequate penetration into the top plate.

Photograph courtesy of Carson Dunlop Associates, a Toronto applied science & domicile inspection firm and home inspection instruction company.

Framing tip : experienced carpenters acquire to place the long centrality of the diamond-shaped cut tip of a common framing nail across the wood grain of the nailed-into member.

This position minimizes splitting. Every bit yous accept the smash out of your nail apron with your left mitt, just place the tip of your third finger on the smash tip and use your thumb and forefinger to curl the blast so that y'all feel its long axis against the flat of your tertiary finger. With the blast in that position, as you start the fastener, place the long axis of the nail point across the wood grain.

A 3 one/2 inch common nail or 16d might exist over-sized for toe-nailing and is probable to split the 2x, especially if nailed near the edges of the lumber.

You originally asked this question in an article on framing connectors. Framing connectors, an alternative to toenailing, are nailed straight into the respective framing members using common, galvanized but short framing connector nails, not full length mutual nails.

Separately, in our article on framing square employ,

at FRAMING SQUARE for BIRDS MOUTH Cutting

we explain how the bird'due south oral cavity cut is located in a rafter by following the rafter's line length from ridge to outer face of wall top plate.

Toe-nailing & Slant-Nailing References

- Breyer,Donald E., Kenneth Fridley, Kelly Cobeen, David Pollock, Pattern of Wood Structures - ASD, McGraw Hill, 2003, ISBN-10: 0071379320, ISBN-13: 978-0071379328

- Harris, Samuel Y. P.East., AIA, Esq., Building Pathology, Deterioration, Diagnostics, and Intervention, ISBN 0-471-33172-iv, John Wiley & Sons, 2001 [General building scientific discipline-DF] ISBN-x: 0471331724 ISBN-thirteen: 978-0471331728

- Wagner, Willis H, Modern Carpentry, Building Construction Details in easy-to-empathize form, [at Amazon] The Goodheart-Wilcox Co., Inc., 1976, ISBN 0-87006-208-5

- Watt, David , Edifice Pathology: Principles and Practice, Wiley-Blackwell, 2d edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- 1994 Uniform Building Lawmaking Tabular array 23-I-Q, Table 23-II-viii-1, Table 25Q

- "Residential Addition Submittal Checklist", City of Ripon, Public Works Department, excerpts from model edifice codes including the UBC nailing schedule, retrieved 5/20.14, original source http://www.cityofripon.org/Building/PDF/09-Residental-Addition.pdf

- Wisconsin Authoritative Code, Chapter SPS 321, Construction Standards, retrieved 5/xx/14, original source: http://docs.legis.wisconsin.gov/code/admin_code/sps/safety _and_buildings_and_environment/320_325/321.pdf

Reader Comments & Q&A

improper toe-nailing: also many nails, split up lumber

Matt: those joist connections don't look too nice to me either.

Matt: those joist connections don't look too nice to me either.

one. The nails are rather shut to the joist terminate. At some of those locations the joist cease is splitting, giving a weak and potentially unsafe structural connexion.

ii. The nails are mis-driven in at least one example (from the joist top) - missing the ledger.

3. The ledger is split at the end from having driven what looks like xiv nails on that side of the outermost joist - and that's before even looking at the other side of the same joist where more nails may be nowadays.

In a 2x6 joist I'd use a total of 8 8d or 10d nails, iv per side, typically 8d in size or in some cases 10d - these are the most-normally-used nail sizes when toe-nailing 2x framing lumber as unless you're using box nails, larger nails tend to split the lumber, especially when, as in your photo, they're nailed too close to the end of the joist.

4. The side by side ledger (near the photo'southward upper right corner) in is roughly cut, non flush with the ledger board, nailed too shut to the joist finish and perhaps also sports likewise many nails. Also many nails actually weaken the connectedness by splitting the wood especially at the joist end.

5. In the ledger lath connection to the construction, there is an exposed nut and washer that look loose but I tin't encounter enough to be sure how this framing fellow member is secured to the edifice;

yous sure want that ledger board to exist properly and securely connected to the building (at what looks like a concrete block or parged foundation wall)

6. I come across no flashing between ledger and building

Picket out: inadequately or poorly attached framing risks structural collapse and injury

Luckily all is not lost. The careful add-on of properly-sized steel joist hangers MIGHT be able to salvage this situation; the down-side is having to drive again more nails into the joist but the hangers can be nailed to the ledger board and those fasteners will be further abroad from the point at which the joist butts into the ledger board.

When I've run into this situation and the lumber was desperately split the contractor agreed to supervene upon it and re-frame the area.

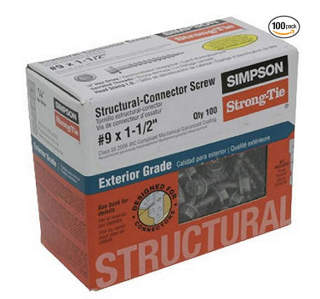

When I've had to apply steel joist hangers or mending plates in these situations I take great care to use the proper fastener; joist hanger nails or screws are manufacturered inthe proper size, both diameter and length, for use with these structural fasteners.

Lookout out

An instance of that production is shown higher up, Simpson Stiff-Tie Structural Screws SD9112R100 No.9 past one-1/two-Inch Structural-Connector Screw - specifically designed for this application.

The visitor says: Simpson Stiff Tie SD Structural-Connector Screws are designed to be used with Simpson Connectors for both interior and outside applications.

Frankly I tin can't run into much from i photo just I hold that some additional measures are appropriate.

I've had a contractor building a deck. They put the initial joist(2x8 treated) too far apart and ended upwards using a reciprocating saw to cut the nails where they went to the ledger.

When they nailed them back in, it appears they did non use galvanized fasteners. The contractor fired the crew, and the new coiffure is at present using joist hangers with the same joist to adhere it to the ledger.

I'm worried that the joists are nailed out now and new joists should be installed, merely the contractor is avoiding it due to the large cost.

Chuck:

Chuck:

If the split your photos show is in a rim joist that sits atop a foundation wall or sill then it's not probable to presage a sag or collapse;

and I'yard unclear how you could run lag bolts up through the lesser of the joist equally it'due south bottom is atop a foundation or sill.

You could, nonetheless, add together steel mending plates to reinforce the surface area of the split.

Shown here is a Simpson TP37 apartment metal mending plate from Simpson Strong Tie

I have a daylight rambler with post & axle down the length of the house in the basement.

For virtually of the length, joists sit on summit of the beam, but for about xi feet at one end the joists are toenailed into the axle and sit on a 2x4 sill nailed along the lesser of the axle, which provides better headroom for that expanse.

I decided to tie every other opposing joist together through the beam in order to amend resist them coming autonomously in an earthquake.

However, when I started looking at the "hidden" (by pipes & ductwork) side of the axle, I found a split running for around 8 feet about 3-4" above the sill.

I'one thousand wondering if that's a problem and, if so, whether running lag bolts upwardly through the beam to reinforce it would assist. Commencement photo shows the construction. Second photograph shows the crack on the opposite side of the beam.

This is the 2d photo meant to become with the previous post.

January

As long as the nails are the right size for the framing members and the right number are used, toe-nailing is perfectly adequate. It does require a bit more adept workmanship to become the connections neat, proper, and strong, simply, and then, a careless worker can foul upward joist hangers but equally hands.

Building a floating deck. Contractor wants to use toe nailing instead of joist hangers. What are your thought

John

In the article above we give the recommended number of toe-nails per side for various dimensions of 2x lumber. That's what I recommend as your guide.

In that location is no single exactly correct answer to your question because forest is a natural material from a living plant that is not absolutely consequent and identical by species nor even from 1 board or 2x to the side by side of the same species, fifty-fifty the same tree.

In a given 2x for example, wet content, forest species, the presence of a knot, the proximity to heartwood, the presence of existing impairment or splits, variations in grain density and management, as well as the smash diameter and even nail cross section shape and the angle to which the nail is driven and the closeness of the boom entry indicate to the end of the member ALL affect the probability that the member will split around the nail, weakening or ruining the connection.

Thanks for asking a bully question. Nosotros will go along this with the article and add other factors in the probability that a piece of forest is going to split or otherwise have a poor nailed connectedness.

How much of a gap can there be between toe-nailed members before the toe-nails start losing effectiveness??

JoAnn the nailing schedule, size, number are given for toe nailing in the article in a higher place.

Your local building department and your codes could require other connectors, depending on where yous live, such as for seismic or high wind conditions.

What I have read here sounds to comprehend my concern somewhat on toe nailing beam to joist. I volition ask though, for my personal use: This involves amalgam a patio cover. In connecting a double 2x6 beam to a 2x6 joist, and if toe nailing, what recommendation in order to pass urban center lawmaking, can be given me on proper nailing to use, boom size, how many and how placed. The rafters/joist volition exist over the double 2x6. Cheers.

Can 4x4 Posts exist toenailed with iv in screws on decking to agree roof

...

Continue reading at FRAMING FASTENERS, NAILS, SCREWS or select a topic from the closely-related articles beneath, or see the consummate Commodity Alphabetize.

Or run into these

Recommended Articles

- CONNECTORS, FASTENERS, TIES

- FRAMING CONNECTORS & JOIST HANGERS

- FRAMING SQUARE for BIRDS Oral cavity CUT

- HURRICANE Necktie Downward CONNECTORS

- STAIR STRINGER to FRAMING CONNECTORS

Suggested citation for this web page

TOE NAILED FRAMING CONNECTIONS at AuditApedia.com - online encyclopedia of edifice & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or meet this

INDEX to RELATED ARTICLES: ARTICLE Alphabetize to BUILDING DECKS & PORCHES

Or utilise the SEARCH BOX found below to Enquire a Question or Search InspectApedia

Or see

Alphabetize to RELATED Manufactures: ARTICLE Index to Building STRUCTURES

Or use the SEARCH BOX constitute below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just beneath, or if you prefer, postal service a question or comment in the Comments box below and we will answer promptly.

Search the InspectApedia website

Annotation: advent of your Comment beneath may exist delayed: if your comment contains an epitome, web link, or text that looks to the software as if information technology might exist a spider web link, your posting will appear subsequently it has been approved by a moderator. Apologies for the delay.

Technical Reviewers & References

Click to Show or Hibernate Citations & References

Publisher InspectApedia.com - Daniel Friedman

Source: https://inspectapedia.com/structure/Framing_Toe_Nailing.php

Posted by: bensonrearach41.blogspot.com

0 Response to "Can You Have Too Many Nails In 2x4 Wall"

Post a Comment